Achieve stable refining with integrated instrumentation and control:

- Real-time sensors: motor load, vibration, temperature, consistency (LC/HC), and plate gap (where applicable).

- Closed-loop load/plate-gap control for target refining intensity and specific edge load (SEL) management.

- PLC/SCADA integration via Modbus/TCP, Profibus, or Ethernet/IP; historian-ready tags.

- Safety: interlocks for seal water, bearing lubrication, and emergency stops with permissive logic.

- Remote support and recipe management for grade changes and startups.

Engineered for high throughput and energy efficiency:

- Low Consistency (LC) models: typical capacity 50–900 m³/h per machine, motor power 75–800 kW.

- High Consistency (HC) models: typical capacity 5–80 t/d, motor power 110–1500 kW.

- Energy: optimized hydraulics and disc patterns reduce kWh/t at target freeness and strength.

- Turn-down: stable operation at 50–100% of nominal flow with consistent plate loading.

- Maintenance windows designed for rapid plate change and seal inspection.

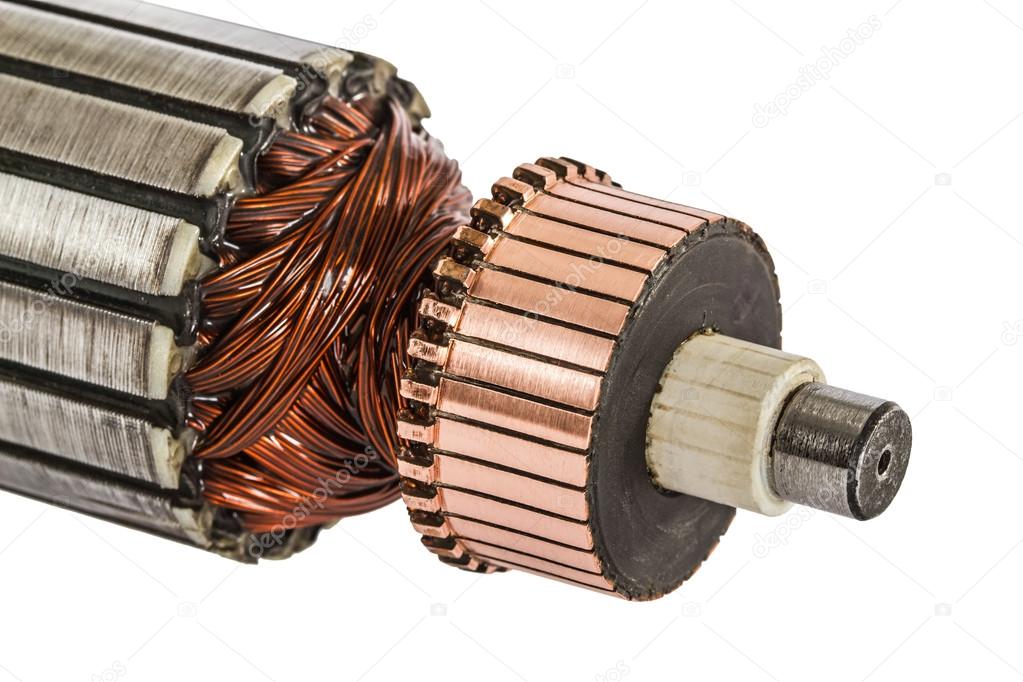

Sizes: LC refiners DN 300–1200; HC refiners rotor diameters 400–1200 mm.

Motor Power: 75–1500 kW depending on model and duty.

Connections: Flanged inlets/outlets; seal water, lubrication, and instrumentation ports standardized.

Operating Limits: Design pressure up to 10 bar(g) (LC) and 16 bar(g) (HC); temperature up to 120°C.

Materials: Carbon steel frame; stainless wetted parts available; wear components with proprietary heat treatment.

Compliance: CE and local electrical standards upon request.

End-to-end services ensure smooth deployment and lifecycle performance:

- Installation & commissioning with alignment, vibration checks, and control loop tuning.

- Training for operators and maintenance on safety, startup/shutdown, and plate changes.

- Preventive maintenance, spare parts, and seal/bearing service programs.

- Performance audits, diagnostics, and reengineering of stock preparation lines.

Specify your process (LC or HC), grade targets, capacity, motor voltage, and any instrumentation requirements. Our engineering team will respond with a tailored proposal.

Prefer to talk? We also respond via phone and email during business hours.